Combining tooling design and optimization with automated production

Tooling design and manufacture have been the cores of precision metal forming. Since establishment, Cheersson has always prioritized tooling design and optimization to meet customers’ demand in deep-drawing and other special metal forming. On the other hand, we incorporate automation into the tooling design and optimization to improve our productivity. Our years of experience give us competitive advantage in precision tooling, progressive tooling, transfer tooling, and mixed tooling. With advanced tooling design, manufacturing capabilities, and automation, we are able to provide precision in tooling design and optimization in production.

Combining process design and improvement with customer needs

Our customers’ needs are the top priorities to our design and manufacturing process. Based on product specific requirement, we continue to improve our process design to provide our customers with the most value-added products and services. The process improvement manifests in our tooling design, material use, process coordination, etc. On the basis of product quality, we optimize the production process and reduce costs incurred during designing single-operation dies.

We will continue to optimize our production process and improve overall efficiency to ensure the best quality of our products and the best value for our customers.

Developing upstream and downstream

Our experience in fasteners and telecommunication structural parts and components enables us to develop and produce core parts of telecommunication equipment. We also invest in the development and deployment of precision welding, automated assembly, calibration technology, and medium materials. Our capabilities expand from 4G products to 5G products, consisting of development and production of filters for telecommunication devices and RF and antenna components. We are also developing and testing 5G ceramic dielectric filters, functional and structural ceramic components for consumer electronics, and related tooling.

Flexible manufacturing ensures timely customer service

We are involved in industries such as telecommunication, automotive, and electrical equipment. With various products and numerous business collaborations, we have developed flexible manufacturing capabilities to quickly respond to our customers’ needs.

We employee ERP system to manage the flow of business processes, compartmentalize the design of tooling, and ensure the flexibility of equipment. Through these steps, we can efficiently switch between products, produce small batch orders, quickly respond to our customers’ changing needs.

Our service is highly recognized among our customers. We have received awards from customers…

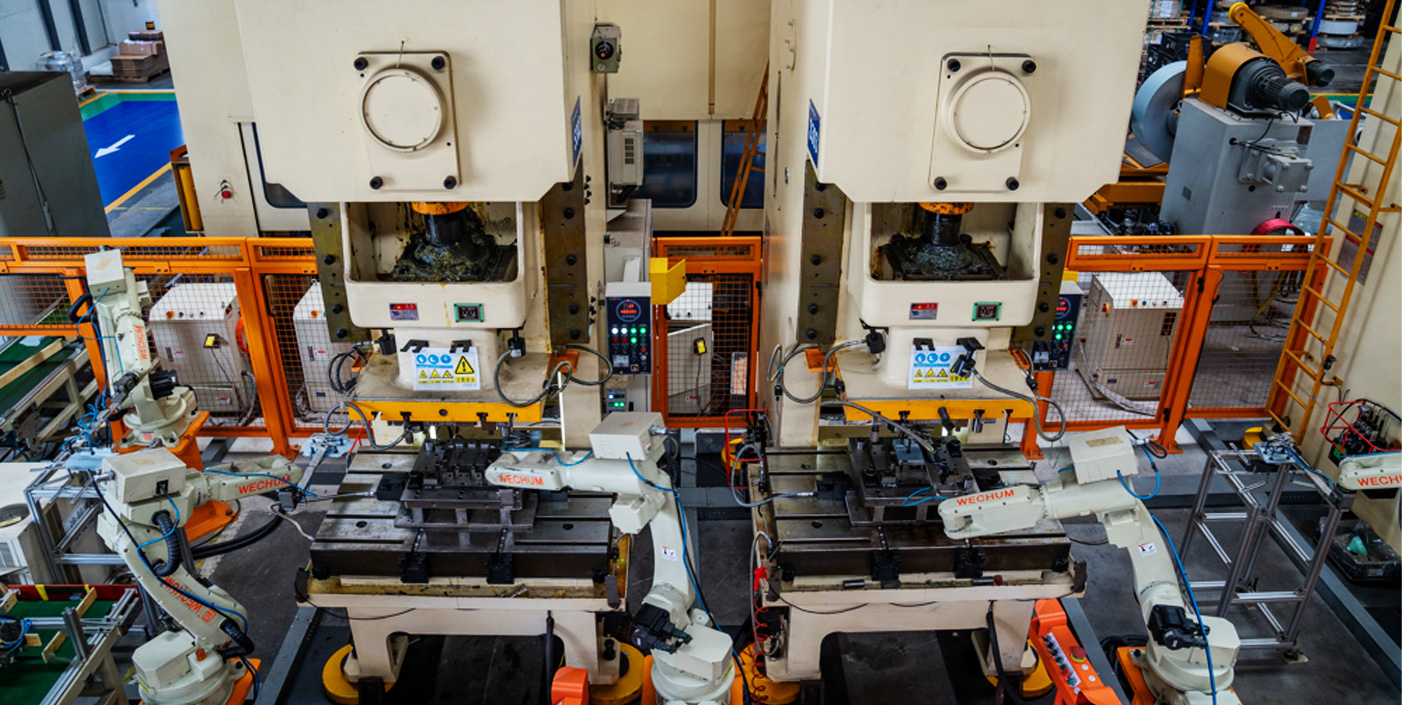

Combining manufacturing efficiency with product reliability

We procure the best manufacturing equipment from around the world, offering reliable products to our customers. In the meantime, we promote automation in our process to increase production efficiency.

Moreover, during the assembly process, we also encourage efficiency and reliability. We develop automated assembly systems in-house to realize highly efficient and reliable assembly process.

We currently develop or modify in-house equipment for stamping, precision processing, assembly, and testing. By doing these, we achieve higher efficiency and more stable and reliable products, laying the foundation for flexible manufacturing.

Contact information

Tel:+86-512-69007888Subscription

Share

We use cookies

We hope to use cookies to better understand your use of this website, which will help us improve your future user experience on our website. For more information on how we use cookies, please see ourPrivacy Policy。